The Cut-to-Size Boom

How our fastest-growing cabinet makers are scaling smarter

Walk into any cabinetry workshop in 2025 and ask one question: “What’s stopping you from growing faster?”

You’ll hear the same answers: not enough time, too much admin, and factory bottlenecks choking output. Yet outside those factory walls, demand is surging.

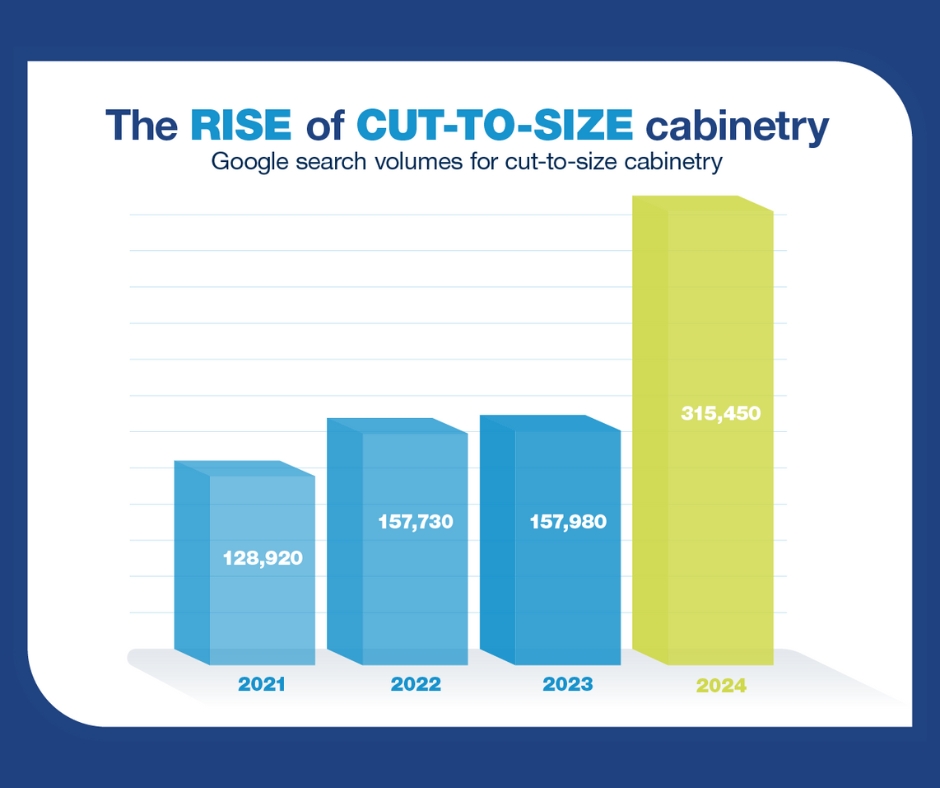

Independent Google data shows that non-branded searches for “cut-to-size cabinetry” in Australia have skyrocketed — jumping from 128,920 in 2021 to 315,450 in 2024. Builders, cabinet makers and renovators are actively searching for faster, more flexible ways to get custom cabinetry.

50 Manufacturers. One Event. One Shared Goal: Growth

That shift in demand brought together more than fifty of the country’s most forward-thinking cabinet manufacturers for the inaugural Cutting Edge Cabinet Makers’ Growth Expo, hosted at the Melbourne Convention Centre in June.

Brought to life by Cabinetry.Online, the event wasn’t about flashy booths or filler panels. It was designed as a playbook for lean growth, focused on automation, pricing that protects margin, smarter layouts, and the tools helping fast-growing shops keep their edge.

More than 70 attendees took part in sessions on lead generation, tech integration, staff onboarding, and how to scale production without adding headcount. Every speaker, every panel, came back to one question: “What are the most profitable manufacturers doing differently?”.

Andrew Steel: From One-Man-Band to Flat Pack Powerhouse

Andrew Steel didn’t just attend; he presented. And his story hit home. Eight years ago, Andrew was pushing his limits running ASC Flatpacks.

“Sweeping the floor at dawn, installing during the day, quoting after hours…it was all hands-on,” he recalled. When demand for flat-pack cabinetry surged, he didn’t just hire more staff; he restructured. He installed two CNCs, added a return-feeder edge bander, and set a foundation for a factory that now runs five days a week, with 60–70 per cent of output dedicated to flat packs.

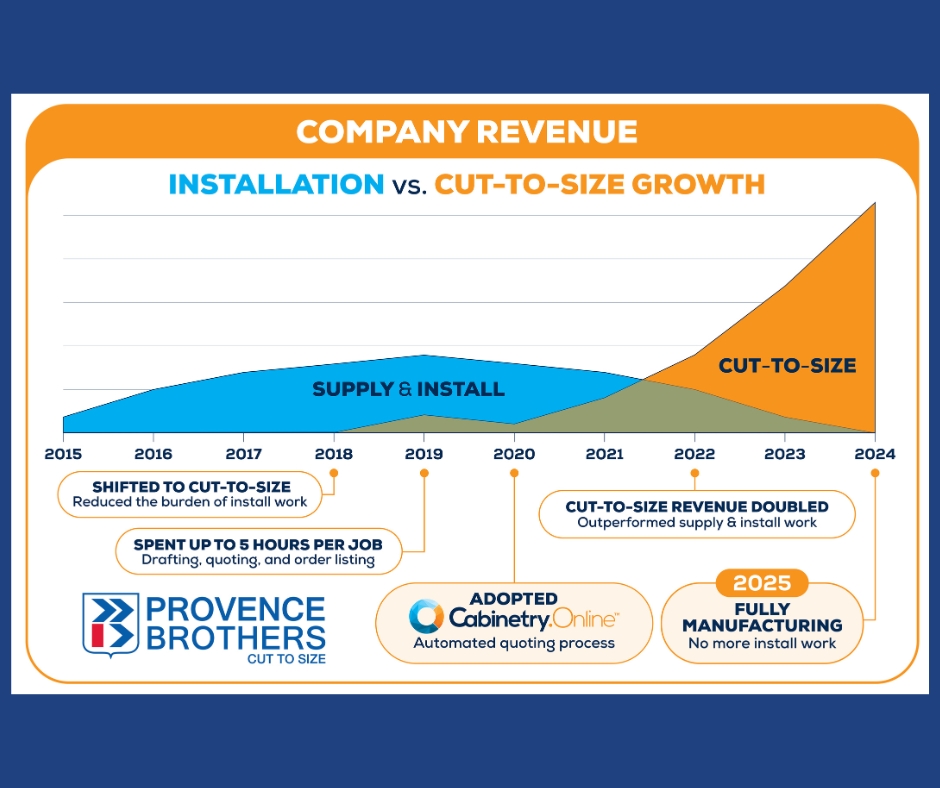

Retief Joubert: Cutting the Chaos at Provence Brothers

Pieter and Retief Joubert of Provence Brothers shared their cautionary tale of trying to do everything, from installs and curved benches to quick favours that drained focus and killed flow.

“Because we could do it, we did do it,” Retief said. “But every extra variation slowed the whole line down.” The turnaround came after reviewing process and discovering something staggering: 15 days of lead time often hid less than 10 minutes of real production.

The pivot included:

✔️ Redesigning the workshop around process, not machines

✔️ Outsourcing non-core tasks

✔️ Adding Cabinetry.Online for automation

✔️ Using goCabinets to generate leads

✔️ Dropping installs and doubling down on cut-to-size supply

“We don’t do everything anymore, but what we do, we do better and faster than anyone else,” Retief added. The company also added an online portal to its website, allowing builders, cabinet makers and DIY customers to order directly, with no back-and-forth or redrawing required.

Systems, Simplicity, and Speed

Manufacturers shared how they were leveraging partners to handle design, quoting and job prep, freeing their internal teams to focus on what matters most. Cabinetry.Online featured heavily, with demonstrations showing how detailing time could drop from 2.5 hours to just 20 minutes per job.

The cabinet makers scaling fastest aren’t doing more work, they’re doing the right work, with the right systems, and the right partners.

They’ve moved from spreadsheets to live pricing.

From quoting manually to letting customers order online.

From chasing every job to building a clear, repeatable niche.

If you’re still quoting by hand, pricing per sheet, or relying on install work to survive, it’s time to step back and ask yourself: “What’s really stopping you from growing faster?”.

All levels of the industry, from builders to large manufacturers are embracing the rise of flat-packs through platforms like goCabinets and Cabinetry.Online, streamlining operations and driving cost-effective solutions.

The demand is real. The systems are proven. The opportunity is now.